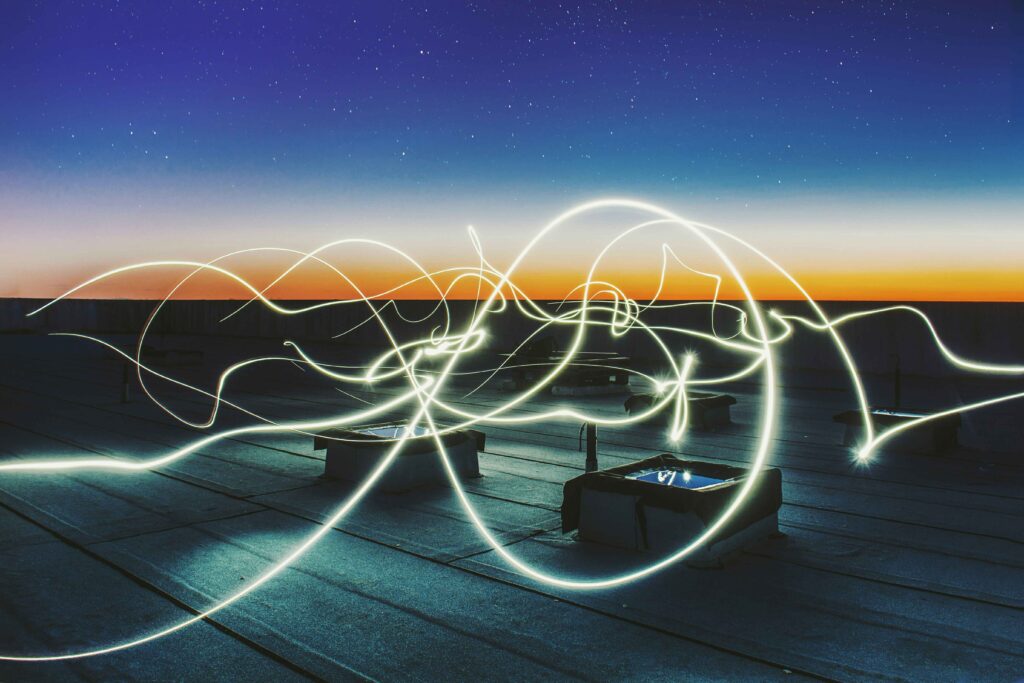

The steering wheel and one of the digital dashboards of the all-electric Mercedes-Benz EQS SUV is seen at the opening of a Mercedes-Benz electric vehicle Battery Factory, marking one of only seven locations producing batteries for their fully electric Mercedes-EQ models, in Woodstock, Alabama, U.S., March 15, 2022. REUTERS/Elijah Nouvelage/File Photo

Analysis: Soaring battery costs fail to cool electric vehicle sales

Buyers around the world are lining up to purchase electric vehicles this year even with sticker prices surging, flipping the script on a decade and a half of conventional auto industry wisdom that EV sales would break out only after battery costs dropped below a threshold that was always just over the horizon.

This year, EV demand has stayed strong even as the average cost of lithium-ion battery cells soared to an estimated $160 per kilowatt-hour in the first quarter from $105 last year. Costs rose due to supply chain disruptions, sanctions on Russian metals and investor speculation.

For a smaller vehicle like the Hongguang Mini, the best-selling EV in China, the higher battery costs added almost $1,500, equal to 30% of the sticker price.

But gasoline and diesel fuel costs for internal combustion vehicles have also skyrocketed since Russia invaded Ukraine, and experts noted that environmental concerns also are pushing more buyers to choose EVs despite the volatile economics.

Manufacturers from Tesla to SAIC-GM-Wuling, which makes the Hongguang Mini, have passed higher costs on to consumers with double-digit price increases for EVs.

More may be coming. Andy Palmer, chairman of Slovak EV battery maker InoBat, says margins in the battery industry are already wafer thin, so “rising costs will have to be passed onto carmakers.”

Vehicle manufacturers like Mercedes-Benz (MBGn.DE) will likely shift increases to customers if their raw material prices keep rising. “We need to keep margins,” Chief Technology Officer Markus Schaefer told Reuters.

But EV shoppers have so far not been deterred. Global EV sales in the first quarter jumped nearly 120%, according to estimates by EV-volumes.com. China’s Nio, Xpeng and Li Auto delivered record EV sales in March. Tesla delivered a record 310,000 EVs in the first quarter.

Here’s a graphic: https://tmsnrt.rs/3OjptBX

‘DIFFERENT KIND OF TIPPING POINT’

“There is a different kind of tipping point that we seem to have hit — an emotional or psychological tipping point among consumers,” said Venkat Srinivasan, director of the Center for Collaborative Energy Storage Science at the U.S. government’s Argonne National Laboratory in Chicago. He said “more and more people” would buy EVs “notwithstanding the cost of the battery and the vehicle.”

This spike in battery costs could be a blip in the long-term trend in which technology improvements and growing production pushed costs down for three straight decades. Industry data showed that the $105 per kilowatt hour average cost in 2021 was down nearly 99% from over $7,500 in 1991.

Here’s a graphic: https://tmsnrt.rs/3JTsiqN

Experts say battery costs could stay elevated for the next year or so, but then another big drop is probably in store as big-ticket investments by automakers and suppliers in mining, refining and battery cell production, and a move to diversify raw material sources, tip the balance from shortage to surplus.

“It’s like a bubble — and for that bubble to settle down, it’s going to be at least the end of 2023,” said consultant Prabhakar Patil, a former LG Chem (051910.KS) executive.

British battery company Britishvolt is due to launch battery production at a 45-gigawatt-hour plant in northeast England in 2024. Chief strategy officer Isobel Sheldon said the advice the company is getting from raw materials suppliers is “don’t fix your prices now, wait for the next 12 months and fix the prices then because everything will be on a more even keel.”

“This over-securing of resources should be behind us by then,” she said.

DEMAND BEATS SUPPLY

The industry has long been awaiting the battery cell cost threshold of $100 per kilowatt-hour, as a signal EVs were reaching price parity with fossil-fuel equivalents. But with gasoline prices soaring and consumer preferences changing, that may no longer matter as much, analysts say.

EV demand in China and other markets “is going up faster than people thought — faster than the supply of materials” for EV batteries, said Stan Whittingham, a co-inventor of lithium-ion batteries and a 2019 Nobel laureate.

Concern about the environment and the climate also has motivated buyers, especially younger ones, to choose EVs over those that burn fossil fuels, said Chris Burns, chief executive of Novonix, a Halifax-based battery materials supplier.

“Many younger people entering the market are making buying decisions beyond simple economics and are saying they will only drive an EV because they are better for the planet,” Burns says. “They are making the plunge even though it would be cheaper” to drive a gas-powered car.

“I don’t think we will stop seeing reports trying to show a trend in battery prices down towards $60 or $80 a kilowatt-hour as aspirational targets, but it is possible that those may never get met,” he said. “However, it doesn’t mean that EV adoption will not rise.”

Reporting by Paul Lienert in Detroit and Nick Carey in London; Editing by David Gregorio

This article was originally published by Reuters.